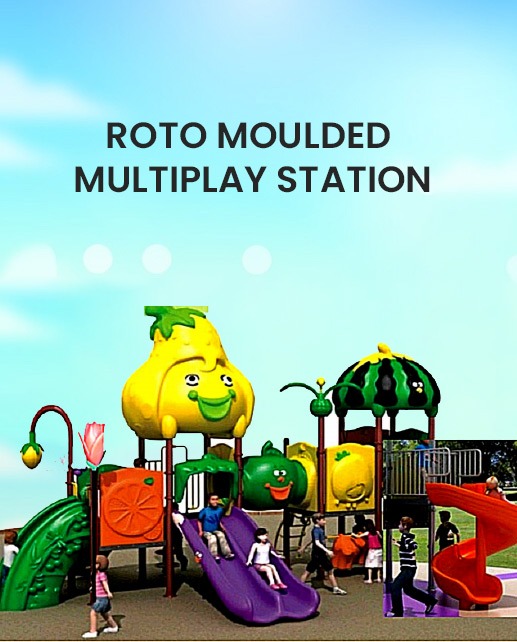

Roto Moulded Multiplay Station

M.S.PIPES:

The M.S. Pipes shall be made of reputed firm ISI mark (Jindal Hissar /Tata/Apollo).

M.S. ANGLE:

The MLS. angles shall conform be of standard make.

NUT, BOLTS AND OTHER FASTNERS:

All nuts, bolts and other fasteners to be used shall be of Hot Dip Galvanized iron.

FIBER REINFORCED PLASTIC MATERIAL:

FRP material shall be made of top quality, polyester resin of reputed brand, MS quality standard glass made of reputed brand only. The moulding of FRP shall be done by contact moulding and has minimum tensile strength of 60 Mpa.

FABRICATION:

Iron component shall be welded by electric arc welding using CO2 as inert gas using best quality welding rods confirming to IS: 814. The welded joints shall be properly grounded and coated with epoxy sealant. All sharp edges and corners shall be properly grounded before painting. All holes shall be drilled by using specially designed hardened drilling fixtures to ensure repeatability & inter chargeability of the components.MOULDING:

Plastic moulded components shall be made of non- toxic materials with UV stabilizers.PAINTING:

All uncoated & non protected surfaces shall first be applied with a coat of red oxide after preparation of surface & then coated with epoxy primer by spray process in a dust free atmosphere. Then a coat of epoxy paint of reputed brand with minimum thickness of 30 microns shall be applied.POWDER COATING:

Powder coating shall be done of pure polyester exterior grade ultraviolent stabilized powder of reputed make which shall be applied after preparation of surface and then treated for adhesion by phosphate chemicals which will be further passivated to stop porosity. The minimum thickness of powder coating shall be 40 microns (Dry thickness). The coated item shall then be cured in oven at 180- degree Celsius for minimum twenty minutes. All Materials shall be first Grade Quality of IS! Mark & ISO Grade & all nuts bolts and other fastners must galvanized and all the items shall be painted PU coating/Powder Coating.